|

||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||

CVB Match 3D: Software for demanding 3D surface inspection

CVB 3D Match

Common Vision Blox

Best choice for imaging complex objects

CVB Match 3D is Stemmer Imaging's first 3D software tool available from

their comprehensive 3D suite for Common Vision Blox. It compares measured

objects to a 3D golden template and offers a solution for challenging

imaging applications requiring extremely accurate, high-speed inspection.

Why is imaging in 3D a complex process?

One of the most demanding imaging applications is the inspection and measurement

of complex freeform objects where dimensional completeness and accuracy

needs to be checked in 3D.

Popular approaches use established 3D sensing technologies based on the

laser striping method, where a laser line stripes the surface of the object

at an a angle as it moves past. Depth information is obtained by measuring

the displacement of the light stripe due to a change of height of the

object and calculated with triangulation.

|

Why is the CVB Match 3D solution different from conventional methods? |

|

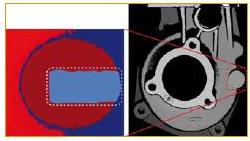

| CVB Match 3D works

differently and offers a new, practical approach for 3D imaging, providing

high accuracy and a processing speed fast enough to keep up with modern

production lines. The 3D image of a perfect sample is captured (Golden Template) and compared to the 3D images of test parts on the production line. The two images are aligned and part deviations can be identified in real time, allowing pass/fail decisions to be made. The algorithm on which the software is based works internally on real 3D point clouds and automatically adjusts position errors or "tipping" and "tilts" in all 6 axes. Consequently, there is no need for accurate part positioning and handling as CVB Match 3D aligns the part image in 3D BEFORE comparison. This means that less mechanical effort is needed and assures high inspection throughput for 100% inline control. |

|

|

How does the CVB Match 3D tool work? |

|||

|

|

|

|

|

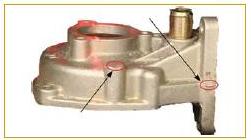

Challenging flaw detection

|

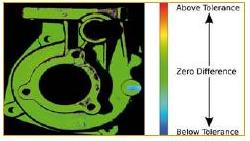

Difference image of test part from a perfect

sample image shows deviations clearly |

A triangulation acquisition device is able to

sense this defect |

Detect shape deviations

|

What are other benefits of the CVB Match

3D tool?

CVB Match 3D tool is a real industrial product easily integrated

into existing machine vision environments.

The software is extremely flexible

and also allows for the inspection of different parts at the same

time. Multiple models can be pre-loaded so that different types

of parts on a single conveyor may easily be inspected enabling

quick product changes without requiring any

special calibration.

The scanned clouds of 3D points are arranged in a sequence and aligned

and compared in a pipeline at an appropriate speed for inline inspections

via software and so eliminating the need for

complex mechanical equipment - cost- and time-saving benefits.

The easy-to-use programming interface includes comprehensive

documentation, source code examples and open

GL visualization as well as sample 3D scans.

Features at-a-glance

*** Software

for demanding real time 3D surface inspection

*** High

accuracy

*** High

processing speed

*** Algorithm

works on real 3D point clouds

*** No

need for accurate positioning of test parts

*** Allows

for the inspection of different parts at the same time

*** Easy

integration into existing machine vision environments

*** Easy-to-use

programming interface

*** Allows

a quick comparison of model and sample

|

CVB software is GigE Vision validated |

|

|

Common Vision Blox is the first, and indeed only, software package in the world to have taken and successfully passed the GigE Vision validation test set by the Automated Imaging Association (AIA). The AIA validation extends far beyond the previous certification, which was based only on the unverified manufacturer assurances that the products met the standard. Users can now feel confidence when they see the official GigE Vision logo, as only products with this logo have been tested by the AIA for full GigE Vision compatibility. |

Adept Electronic Solutions are "The Machine Vision and Imaging Specialists" and distributor of Stemmer Imaging products in Australia and New Zealand. To find out more about any Stemmer Imaging machine vision product please email us at: adept@adept.net.au or call us at Perth (08) 92425411 / Sydney (02) 99792599 / Melbourne (03) 95555621 or use our online contact us page.

|

If you like this page, please recommend and share it. |

|||

| More | |||