New

1.45MP camera with new Cameralink - Jai CB140MCL/CM140MCL

New

1.45MP camera with new Cameralink - Jai CB140MCL/CM140MCL

The new CB-140MCL and CM-140MCL are digital progressive scan 1.4 megapixel

CCD cameras with a new digital Mini Camera Link (MCL) interface. Based upon

the design for Jai's popular analog CV-A1 and CV-A2 cameras this camera

comes loaded with features such as optional Power over Camera Link (PoCL),

auto-iris, control tool and an automatic LVAL synchronous / asynchronous

operation. Both cameras are offered in either monochrome (CM-140MCL) or

colour (CB-140MCL).

The JAI CB-140MCL/CM-140MCL features a large high sensitivity ½" CCD sensor and operates at up to 31 frames a second at full SXGA resolution (1380 (h) x 1040 (v) active pixels) in continuous operation mode. This differentiates this camera as one of the fastest high performance cameras in its class.

The JAI CB-140MCL/CM-140MCL CCD camera comes with a new MCL (mini CameraLink) interface allowing a host of new advantages including reduced size and a new Power over CameraLink (PoCL) feature. The CB-140MCL and CM-140MCL have a compact 29x44x66mm body which matches the size of the analog models allowing machine vision users to easily convert from analog to the newer digital range without timely and costly mechanical/optical redesign. JAI's new optional PoCL feature cleans up the problems of having messy cable clutter with its clean one-connector solution at no extra cost.

JAI's CB-140MCL/CM-140MCL CCD camera also comes with a smart automatic Iris function making it suited for most outdoor applications. In an outdoor application such as traffic infringement or surveillance where varying levels of sunlight can be a barrier the camera can automatically adjust to a wide range of light levels.

The JAI CB-140MCL/CM-140MCL CCD camera comes with easy-to-use control software for camera configuration and setup. This connectivity from the software to the camera runs over the CameraLink connection and so requires no extra cables. The software communicates with the camera using ascii commands so industry standard communications packages such as HyperTerminal can also be used or a user may choose to write his own communications easily and simply.

A new function implemented in the CB-140MCL/CM-140MCL CCD camera allows the camera to be triggered while the CCD sensor is still reading out. Typically this would cause reset feed-through on the video signal causing a corrupted image. This new feature avoids this problem while still allowing for asynchronous trigger mode.

Typical application areas for the CB140MCL / CM140MCL include:

- Automotive inspection (e.g. High accuracy gauging & process verification)

- Pharmaceutical inspection (e.g. blister pack content, fluid fill levels)

- Beverage industry (e.g. inspection of defective bottles and fill levels)

- Food sorting

- Electronics inspection

JAI's CB-140MCL CCD camera overshadows its competitors with good frame speeds, resolution levels and a new MCL function packed with quality features suited for most tight-fit and demanding machine vision applications.

Adept Electronic Solutions are the machine vision and imaging specialist providing expert advice and timely support. To find out more about the JAI CB-140MCL/CM-140MCL CCD camera or any model from JAI's range of cameras please contact us or call us at Tel Sydney (02) 99792599 / Perth (08) 92425411

Interlaced

goes digital - AVT interlaced series

Interlaced

goes digital - AVT interlaced series

AVT's interlaced range of 6 Guppy cameras are equipped with highly-sensitive

interlaced sensors and have forged a link between formerly analog-only interlaced

technologies and digital firewire interfaces. The Guppy replaces the need

of using framegrabbers with its own integrated smart functions and API features.

But despite its remarkable price/performance ratio the true strength of

the Guppy camera is in its ability to package so much into its ultra-compact

and space-saving body.

The new interlaced cameras are based on the same platform as the other Guppy models but are equipped with 1/2" or 1/3" Sony interlaced CCD sensors (EIA, CCIR) with picture resolutions starting from 500(h) x 580(v) in the F-29B/C to as high as 768(h) x 492(v) in the F-38B/C. The Guppy interlaced range operates at frame speeds of either 25 or 30 frames per second and 60 fields per second. Available with black/white and colour options, this range also offers 2 versions with near infrared (NIR) 1/2" sensors. All models within the Guppy family including the interlaced versions come equipped with the firewire (IEEE 1394a) digital interface.

The Guppy cameras have new integrated smart functions and API features. Some of the features added to the Guppy include single/multi/free-run shot modes, 1 programmable input, 3 programmable outputs and a RS-232 port. These features now allow the camera to independently capture a sequence of images.

One size fits all takes on a new meaning for this tiny camera with its overall form at just 48.2mm x 30mm x 30mm (L x W x H). It has to ability to fit snuggly and compactly into space-constrained applications and to be mounted in weight limited situations where the camera for example may need to be moved at the end of a robot arm.

The Guppy has made the transition from analog to digital a lot simpler. The best of both worlds have truly come into the AVT Guppy family - Interlaced Goes Digital

Adept Electronic Solution (AES) is a specialist Australian/New Zealand distributor of machine vision systems and image analysis software. With a broad range of world class machine vision hardware and software products, AES provides a complete machine vision systems solution.

To receive more information or to purchase contact Adept Electronic Solutions at adept@adept.net.au Telephone one of our expert sales engineers in Perth (08) 92425411 or Sydney (02) 99792599.

Machine Vision Appliance for any vision user - iPD VA15

Aug 2007

The VA15 unit is housed in a ruggedized box measuring 9.5(w) x 16(l)

x 5(h) cm and its 1X processing scale is supported by 128MB of program

memory and 64MB of storage memory. The VA15 supports only 1 monochrome

analog camera with 640x480 pixel resolution at up to 60fps.

Unlike its traditional smart camera counterparts, the VA15 incorporates the "smarts" inside the camera controller, as opposed to the camera head. This has the benefit of easier integration since it can be positioned in a chassis alongside other industrial automation controllers. With its smaller camera size it is flexible to install and is suitable for tight-fit machine vision applications.

Interfacing the VA15 is a snap. The small VA15 body is fully equipped

with industrial grade opto-isolated inputs and outputs that are wired

using removable screw terminal connectors. Its configurable opto-isolated

input-output ports provide the vision user with safe connectivity and

flexibility. The VA15 also has its own ethernet port (10/100/1000 Mbps),

an RS232 port, and 2 USB 1.1 ports. A visible LED light is coupled to

each connection, reflecting the active state of the signal. The I/O port

together with all external interfaces is conveniently accessible on the

front of the unit facing the user.

Easy-to-use machine vision software is pre-installed and ready to run,

thus eliminating installation and revision control problems. It is remotely

programmed via an ethernet connection and comes installed with iNspect

Lite software that offers comprehensive functionality for including location

finder; distance, circle, bread and angle measures; counting and surface

defect analysis; intensity measures, template matching tools and 2D and

1D barcode reading. Configuration of the machine vision software is guided

by bullet options, sliders and simple dialogs that are designed for non-vision

factory floor personnel. Once configured the unit runs autonomously and

can be maintained by operators. Inspections can be monitored remotely

from any computer with access privileges.

The VA15 machine vision toolset is well equipped and suitable for a range of quality control applications including assembly verification, part identification, measurements, flaw detection and object location.

Key Features include:

- No software to install

- Powerful embedded processor

- Insures fast inspection times

- Online or offline inspection

- Quick connect/disconnect wiring

- Easily integrates into factory environments

- Universal solution for end-users, integrators and machine builder

To receive more information or to purchase contact Adept Electronic Solutions at adept@adept.net.au Telephone one of our expert sales engineers in Perth (08) 92425411 or Sydney (02) 99792599.

New 3 CCD RGB GigE camera from Jai - CV-M9GE

Aug 2007

JAI's

already popular and proven 3CCD camera CV-M9CL has taken an important

step into the future. For the first time Jai has leveraged the combination

of advanced 3CCD RGB colour vision technology and the easy-to-use GigE

Vision standard interface with the new CV-M9GE.

JAI's

already popular and proven 3CCD camera CV-M9CL has taken an important

step into the future. For the first time Jai has leveraged the combination

of advanced 3CCD RGB colour vision technology and the easy-to-use GigE

Vision standard interface with the new CV-M9GE.

The GigE Vision standard interface together with programmable GPIO (General purpose input/output ports) used in the high speed camera takes the trouble out of integrating advanced 3CCD prism colour technology into even the most demanding machine vision applications.

The new GigE high speed cameras similar to their older counterparts can be widely used across a diverse range of applications that require precise colour measurement. The CV-M9GE 3CCD camera is suitable for use in any application where true colour and high fidelity are required along with ease of integration.

Some applications include:

Print inspection, food sorting and inspection, flat panel quality verification, medical diagnostics such as skin screening, agricultural applications and others.

Based on 3CCD prism technology, the high speed camera provides full XGA (1024 x 768) resolution for each of the Red, Green and Blue colour bands. The clear spectral separation between the three colour bands gives this camera the ability to define and detect colours that would not be possible to detect with a 1CCD colour camera.

The CV-M9GE 3CCD camera features both manual and automatic one-push white balance adjustment, making it easy to achieve the correct setting for a wide range of colour temperatures and under difficult lighting conditions. Alternatively the white balance can be adjusted by individual settings in the Red, Green and Blue channels, while maintaining a consistent and high signal/noise ratio in each channel. Sophisticated colour shading correction offers a flat field which is often a weak point with low quality 3CCD cameras.

The high speed CV-M9GE 3CCD camera can be operated in Continuous (free-run) mode at 30 frames/second or in an external trigger mode. The Edge Pre-Select trigger mode uses a pre-defined exposure time whereas the Pulse Width Control trigger mode sets the exposure time based on the width of the trigger pulse.

The CV-M9GE 3CCD camera also features a Sequencer trigger mode that permits on-the-fly change of a combination of gain, offset and Region of Interest (ROI). Another useful industrial camera function is "delayed readout" where images from simultaneously triggered cameras are read out in sequence to avoid congestion on the Ethernet interface.

GigE Vision industrial cameras use standard Cat5e or Cat6 cabling and do not require a dedicated frame grabber in the PC. This translates directly into cost savings and shorter "time-to-market" for development projects.

The new Jai GigE CV-M9GE 3CCD camera features can be summarized:

- The GigE Vision standard interface for standard Cat5e or Cat6 cabling

up to 100m distances

- Self-describing, easy to use with 3rd party software libraries (GenICam)

- Programmable GPIO (General purpose input/output ports)

- Standard trigger modes with "pre-select" or "pulse

width" exposure

- Sequencer trigger mode that permits on-the-fly change of a combination

of gain, offset and Region of Interest (ROI).

- Delayed readout" where images from simultaneously triggered cameras

are read out in sequence.

- Manual and automatic one-push white balance adjustment (CV-M9 GE).

Machine vision integrators and machine vision users worldwide for the first time have access to industrial cameras that combine advanced 3CCD RGB color vision technology with the easy-to-use GigE Vision standard interface to deliver a yet once again winning industrial camera from Jai.

Adept Electronic Solutions are the machine vision and imaging specialist

providing expert advice and timely support. To find out more about the

JAI CV-M9GE 3CCD camera or any model from JAI's range of cameras please

contact us or call us at Tel Sydney (02) 99792599 / Perth (08) 92425411

Machine

Vision Appliances go faster - VA40E and VA50E

Machine

Vision Appliances go faster - VA40E and VA50E

Aug 2007

iPD's VA40E and VA50E provide end users and system integrators with a

faster performing machine vision inspection system with a host of new

upgrades and improvements. iPD has not only doubled its standard onboard

memory in the VA40E but has also included newer communication flexibility

for both versions - with USB 2.0 and GigE. The new iPD VA40E and VA50E

machine vision appliances are more power-efficient and have a larger temperature

tolerance in most industrial operating environments.

The new iPD VA40E and VA50E machine vision appliances come upgraded with

1.5 times the processing power of its older version and a new GigE communication

protocol. GigE Vision (Gigabit Ethernet) is the industry standard 1000Mbps

ethernet LAN protocol adopted for machine vision and optimized for image

transfers. It has been designed to provide greater flexibility for high

performing vision inspection catering for industrial machine vision applications.

The new VA40E/50E machine vision appliances support multiple cameras for

machine vision applications that require multiple views of a part, or

even different parts simultaneously. This integrated functionality provides

a cost-effective and less complex solution than smart cameras. In addition

these machine vision appliances are compatible with different camera types

that afford you flexibility in design and upgrade options as your application

needs change.

Machine

Vision Appliance VA40E

Machine

Vision Appliance VA40E

Interfacing the VA40E machine vision appliance is easy. It is fully equipped

with industrial grade Inputs and Outputs that are broken out to removable

screw terminal connectors or opto-isolated modules. Serial communication

options include RS-232, USB 2.0 and GigE for connecting into the factory

network. All physical connections are located on the rear panel with status

lights available on the front.

Application setup software is preinstalled and ready to run; thus eliminating

installation and revision control problems. The VA40E machine vision appliance

offers two distinct software interfaces, called iNspect and Sherlock.

iNspect provides application versatility and ease-of-use, allowing you

to setup and deploy a machine vision solution in a matter of minutes.

For more complex tasks Sherlock provides even greater flexibility and

control, giving you the tools and capabilities at your fingertips to apply

to almost any application. An additional benefit of the VA40E is that

it supports 3rd party software on a Windows platform.

Machine Vision Appliance VA50E

Machine Vision Appliance VA50E

The new VA50E machine vision appliance provides two cameralink camera

inputs that allow you to image and inspect from two linescan cameras simultaneously.

It is supported by various cameras of different resolutions that typically

range from 1024 to 8096 pixels. The VA50E machine vision appliance provides

the timing inputs and outputs for synchronizing the cameras to the speed

of the moving part or surface. It caters for line scan machine vision

applications such as cylindrical unwrapping, large format imaging of moving

surfaces or continuous web inspection.

The 24V compatible I/O is broken out to removable screw terminal connectors

or opto-isolated modules. The VA50E machine vision inspection system is

equipped with a standard serial and a GigE interface for communicating

with complementary devices or connecting into the factory network. User

input is typically through keyboard, mouse and monitor attached to the

unit, but is also supported remotely through the GigE connection to a

common operator interface. All physical connections are located on the

VA50E rear panel with status lights available on the front.

Application setup software is preinstalled and ready to run, thus eliminating

installation and revision control problems. For maximum flexibility the

VA50E machine vision inspection system is supported by our Sherlock inspection

software; a powerful and proven tool that has been used in thousands of

installations worldwide. Sherlock's configurable interface allows you

to quickly prototype benchmark and deploys inspection solutions. In addition

to its extensive library of preprocessors and machine vision algorithms,

Sherlock supports inline scripting, user custom tools and a customizable

operator interface.

Vision Appliances are machine vision inspection systems well equipped

to interface complementary equipment and the factory enterprise. The software

tools provide standard support for discrete I/O, serial and TCP/IP connections

along with Ethernet/IP and Modbus industry protocols. Machine Vision Appliances

connect directly with a variety of PLCs, robots, motion controllers and

other factory floor devices. Dalsa iPD's latest version of iNspect software

- version 1450 comes installed on Machine Vision Appliances and now directly

connects with Allen Bradley PLCs making integration into plants simple

and easy.

iPD's new VA40E and VA50E machine vision appliances have brought the

Machine Vision appliance's increased processing punch together with the

new high speed GigE to deliver greater flexibility and applicability in

today's industrial machine vision applications.

Adept Electronic Solution (AES) is a specialist Australian/NZ distributor

of machine vision systems and image analysis software. With a broad range

of world class machine hardware and software products, AES provides a

complete machine vision systems solution.

To receive more information or to purchase contact Adept Electronic Solutions

at adept@adept.net.au Telephone one of our expert sales engineers in Perth

(08) 92425411 or Sydney (02) 99792599.

1.4MP

High-speed GigE camera - Genie HM1400

1.4MP

High-speed GigE camera - Genie HM1400

Aug 2007

DALSA's new Genie high speed GigE Vision cameras are compact easy-to-use digital cameras engineered specifically to accommodate most industrial machine vision applications. Dalsa's high speed Genie cameras use Dalsa exclusive sensor technology to provide unprecedented image acquisition quality in a small compact form factor that allows them to be implemented into most tight-fit applications that require high performance. With an uncompromised signal-to-noise ratio all Genie high speed cameras transmit digital images over the Gigabit-Ethernet interface with the use of standard CAT-5e and CAT-6 cables for up to 100m. The Genie series comply with the international GigE interface standard called GigE Vision released by the AIA (Automated Imaging Association) and therefore are plug and play replaceable with other GigE Vision cameras. They are supported with Sapera™, Dalsa's machine vision software offering fast, simple setup with unique data reliability features.

The Genie HM1400 features 1400x1024 pixel resolution at capture rates up to 75fps at full resolution and 300 fps at VGA resolution while maintaining a crisp image quality. Its global electronic shutter with exposure control allows the HM1400 to handle the capture of very fast moving objects. On-board flat-field correction allows users to flatten the effects of uneven lighting and to correct for pixel variations therefore simplifying software analysis. The anti-blooming feature of the Genie HM1400 provides the ability to minimise artifacts due to the effects of very bright points or areas of an image. Unlike many other GigE cameras the Genie series are compatible to most gigabit ethernet chipsets and do not rely on some specific features of a limited number of chipsets on the market. They produce high data rates over networks with very limited CPU involvement, leaving the CPU for image processing tasks.

DALSA's Sapera™ software enables users to benefit through its fast

and simple camera setup. As soon as the camera is connected to the system,

auto discovery automatically identifies the camera and communicates all

of the supported features to the Sapera™ environment greatly facilitating

system setup and configuration. Moreover the Genie Framework package found

in the Sapera™ software employs DALSA's Trigger-to-Image reliability

framework. This allows it to dependably capture and transfer images from

the camera to the host PC. Trigger-to-Image reliability (T2IR) is an engineering

design framework exclusive to Dalsa, ensuring the reliability of the image

acquisition system by supplying the key design elements needed to:

1) Secure the image acquisition process

2) Permit error identification, and

3) Provide a recovery mechanism if and when errors do occur

In summary the Genie HM1400 high speed monochrome camera features:

- 75fps in full resolution of 1400x1024

- Small compact form factor

- GigE Vision standard allowing cable lengths of up to 100m and transfer

rates of up to 100Mbps

- Global electronic shutter with exposure control

- Simplified setup with Sapera™ software

- Uses standard PC and server Ethernet ports and hardware

- Higher frame rates achievable in partial scan

- Programmable LUT

- On-board flat-field correction

- 1000x Antiblooming

To find out more about the Genie HM1400 high speed monochrome camera or any of the Genie series feel free to contact one of the expert vision engineers at Adept Electronic Solutions.

To receive more information or to purchase contact Adept Electronic Solutions at adept@adept.net.au Telephone one of our expert sales engineers in Perth (08) 92425411 or Sydney (02) 99792599.

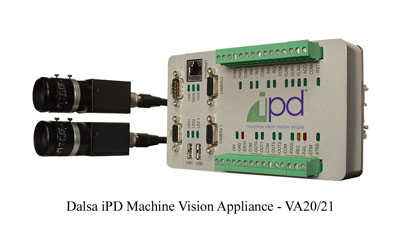

Dual-camera Machine Vision Appliance - iPD VA20/21

Aug 2007

The VA20 provides end users and system integrators with a powerful and

practical machine vision solution for single or dual camera applications.

This DIN mountable system has been specifically designed to minimize integration

and speed deployment by providing easily accessible control and intuitive

software setup.

The VA20 unit doubles in its memory capability accepting up to 128 solutions

as compared to only 8 in the single camera Vision Appliance - VA15. Given

this greater workload the VA21 unit now has 2 GB of storage memory. Capable

of taking 2 monochrome analog cameras the VA20 now accepts 1024x768 resolution

at up to 60fps.

The VA20 is a dual camera vision appliance. Unlike its traditional smart

camera counterparts, the VA20 incorporates the "smarts" inside

the camera controller, as opposed to the camera head. This has the dual

benefit of easier integration, since it can be positioned in a chassis

alongside other automation controllers, and smaller camera size, thus

making it suitable for tight-fit applications. In addition, the built-in

dual camera capability provides a cost-effective solution in multi-camera

applications.

Interfacing the VA20 is a snap. The unit is fully equipped with industrial

grade Inputs and Outputs that are wired using removable screw terminal

connectors. A visible LED light is coupled to each connection that reflects

the active state of the signal. The I/O, together with all external interfaces,

is conveniently accessible on the front of the unit facing the user. Application

setup software is preinstalled and ready to run, thus eliminating installation

and revision control problems.

The VA20/21 offers two distinct software interfaces called iNspect and

Sherlock 7. The Sherlock 7 software application is only supported on the

VA21. Some of its new features added include a 360 degree rotation of

parts, concentricity and rake measurements, flashing features, iLabel

and optical character recognition (OCR) identification.

Less integration, quick software setup, multiple cameras... with the VA20 Vision Appliance, integrating machine vision just got a whole lot easier!

Key Fe a t u r e s:

- Compact DIN mountable system

- Single or dual camera inspections

- Suitable for tight-fit camera applications

- No software to install

- Powerful embedded processor ensures fast inspection times

- Online or offline inspection

- Quick connect/disconnect wiring

- Easily integrates into factory environments

- Universal solution for end-users, integrators and machine builders

The VA20 is available in two versions. The VA20 version requires an external

PC/Laptop connection with Microsoft web browser for remote setup. The

VA21 version contains additional hardware that allows users to setup and

run applications locally. The Sherlock software application is only supported

on the VA21.

To receive more information or to purchase contact Adept Electronic Solutions at adept@adept.net.au or Telephone one of our expert sales engineers in Perth (08) 92425411 or Sydney (02) 99792599.

- August 2007

info@adeptturnkey.com.au

Perth:

(08) 9242 5411

Sydney:

(02) 9905 5551

Melbourne:

(03) 9384 1775