|

||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||

Ore3D Ore Sizing

Back to the Vision Systems

Back to the AES Systems

| •

Measures in 3D |

•

No lights = consistent accuracy |

•

Saves costs |

•

Easy to interface |

•

On-Line and Automatic |

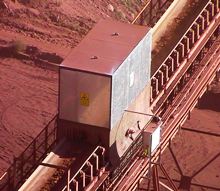

About the Ore3D system

Ore3D is a unique fragmentation measurement technology developed for

the minerals processing industry that is novel and well proven.

The Ore3D Ore Sizing sensor is the latest breakthrough in online, non-contact,

ore-sizing technology that can be retro-fitted over a conveyor belt carrying

ore. It has been operational on sites for years, requires very little

maintenance and has exceeded all expectations in performance and accuracy.

The Ore3D Ore Sizing sensor is the latest breakthrough in online, non-contact,

ore-sizing technology that can be retro-fitted over a conveyor belt carrying

ore. It has been operational on sites for years, requires very little

maintenance and has exceeded all expectations in performance and accuracy.

Built upon the already proven and reliable, OOS technology Ore3D

offers high-speed size distribution measures, accurate fines detection,

volume and bulk density measures and many more advanced features.

With many installed sites running 24/7 for up to 12 years with

little if any maintenance, Ore3D offers a very dependable,

consistent technology. Download

Ore3D brochure

Benefits

Ore3D allows Miners and Minerals Processors to measure the size of their

ore at any stage of the comminution process: as ROM after blasting, post

primary, secondary or tertiary crushing and as feed to SAG mills. It allows

minerals processors to provide tighter control of their processes and

also measure performance and influence blasting operations in the mine

to optimise the complete mining chain for total

and maximum efficiency. It also allows the detection of oversize

to avoid potential plant damage, can detects

screen wear or failure and triggers an alarm in case of oversize

contamination.

The technology offers data feedback to allow control systems and operators to tighten the control of their processes and increase efficiency. It can improve extraction, increase throughput and reduce consumables and running costs. The bottom line is that these benefits can significantly reduce costs and increase profits.

How It works

Ore3D is a rugged and online instrument designed to fit over

conveyor belts to produce continuous size distribution measures.

It uses a technique called "active stereopsis"

to measure the burden of ore in 3 dimensions on a moving conveyor belt

. The technique measures individual fragments of ore on the burden of

ore on the belt as they pass under the system, processes them with sophisticated

software algorithms to produce mass measures, and outputs accurate cumulative

% passing size distribution curves, repeatedly, 24/7.

The size distribution data is derived with industry-standard techniques

so that it matches those generated by traditional sieving tests. Any number

or selection of points on the size distribution curve can be output and

used as inputs for feedback or feed-forward control or simply as trending

data for operators in the control room.

| Ore3D features and advantages |

|

|

| • Determines full size distribution |

• Detects oversize | |

| • Measures Volume -> Bulk Density | • Measures in 3D | |

| • Rapid update rate – 50 to 200 scans per second | • On-line and automatic | |

| • Instant and continuous | • Detects oversize | |

| • Can produce shape and grade measures | • Auto- detects part of fully empty belt - no weightometer | |

| • Requires very low maintenance - no lights | • Easy to interface to any plant control system | |

| • Corrects for parallax and perspective distortion | • Non-contact sensing | |

| • Uses high contrast features for better sizing accuracy | • Automatically recognises empty or partially empty belts | |

| • Provides system diagnostics | • Uses NO lights so measurement remains accurate | |

| • Solid State low power laser 100,000hrs MTBF | • Requires very little maintenance | |

| • Can be used for operator trending feedback | • Easily interfaced to SCADA via PLCs or direct |

Being a 3D system, Ore3D can measure an accurate size for particles regardless of their distance from the camera and can measure the volume of ore passing which can be useful for optimising loading operations. Measuring volume with a weightometer measurement also allows for Bulk density measures. The system can also measure the surface profile of fragments and so determine shape parameters.

The system captures images continuously, 50 to 200 times-per-second,

so that every part of the ore burden on the belt is sampled.

An empty belt can be detected easily and automatically because it has

its unique 3D shape when empty. Ore3D avoids mistakenly measuring the

belt when empty or partally loaded. It avoids having to restrict the view

on the edges of the burden where often large particles percolate to, as

is required for 2D systems.

Ore3D measures the shape of a high-contrast thin laser line across the

belt as it deforms to the shape of the burden. The narrow line and high

contrast enables the system to measure with very high precision using

sub-pixel interpolation techniques.

Ore3D requires no lighting. Area lighting ages from the first day of operation, leading to a shift in brightness and uniformity causing a continuous drift in the data measured and a constantly degrading accuracy. Ore3D avoids this problem. Using a long-lifetime solid state laser that needs no maintenance, the system runs at the same brightness and uniformity for 100,000 hrs (MTBF) before failing completely and triggering a system alarm to prompt a laser change. Ore3D's measures remain reliable and repeatable for years without the need for recalibration.

| Applications | |

| •Optimisation of feed size distribution into grinding mills | • Monitoring oversize and fines in product streams (lump in fine) |

| • Monitoring crusher performance | • Size control for product quality, e.g. quarries |

| • Sorting and recovery - flow rate and size required, e.g. diamond mining | • Volume flow rate for maximised belt loading |

| • Truck-fill volumes | • Plant audits |

| • Monitoring size fractions in split ore streams | • Measurement of fragmentation from varying blasting designs |

| • Product-quality monitoring at ports after blending | • Monitoring screen wear and damage |

| • Detection of oversize in feed material |

|

|

|

|

|

If you like this page, please recommend it and share it. |

|||

| More | |||