|

||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||

Part One: The science of a Hyperspectral Line Scan Camera

Go to Specim

Go to FX Series

Go to Hyperspectral Cameras

| How a Pushbroom hyperspectral Camera works | ||

|

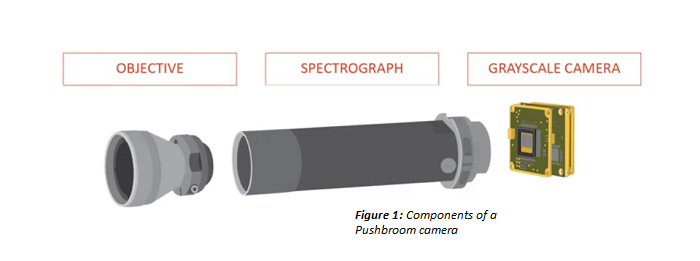

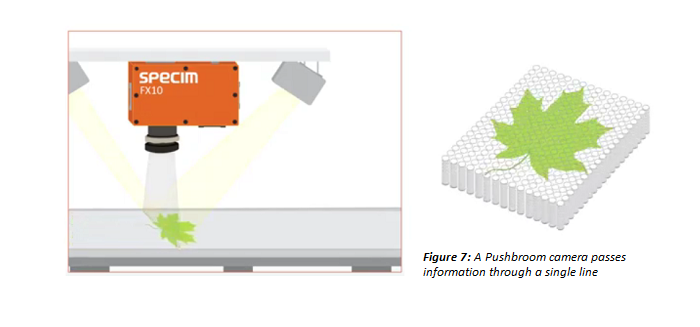

Pushbroom Hyperspectral imaging is moving from what have traditionally been research applications, into commercial and industrial applications and will become a technology that we see and interact with in every part of our daily lives. What is it and how does it work? The first part in this two part series examines what makes up a pushbroom hyperspectral camera. It describes the key components and how they work to collect hyperspectral data. The second part will investigate how the data is analysed in order to detect or determine the chemical makeup of the object being imaged. A Pushbroom camera otherwise known as a line scan hyperspectral camera, is a device used to collect full spectral and spatial information of a target line by line. The key components of a Pushbroom camera include an imaging spectrograph, a grayscale camera and an objective lens, which must be optimised for the camera's specific wave length range.

|

||

|

||

|

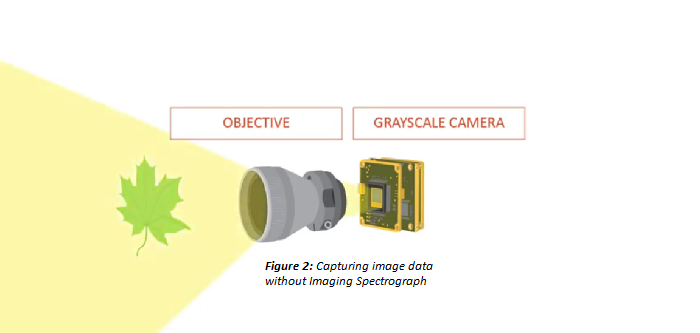

When recording a normal black and white image, all that is required is a grayscale camera and an objective. The objective projects the target to the camera's sensor where the image is recorded.

|

||

|

||

|

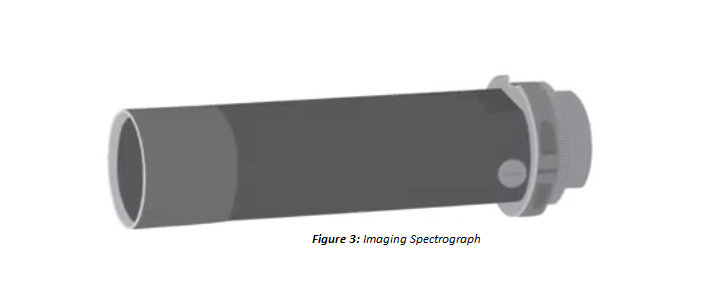

However, if our need is to record a target's hyperspectral data, the imaging spectrograph component is fundamental.

|

||

|

||

|

So what are the working principles of

an imaging spectrograph?

|

||

|

|

|

|

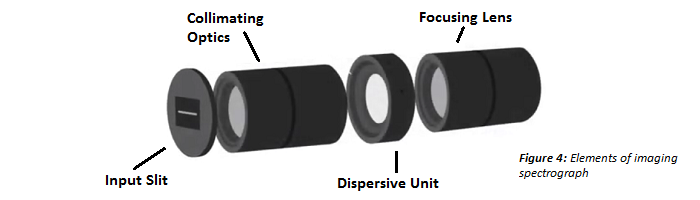

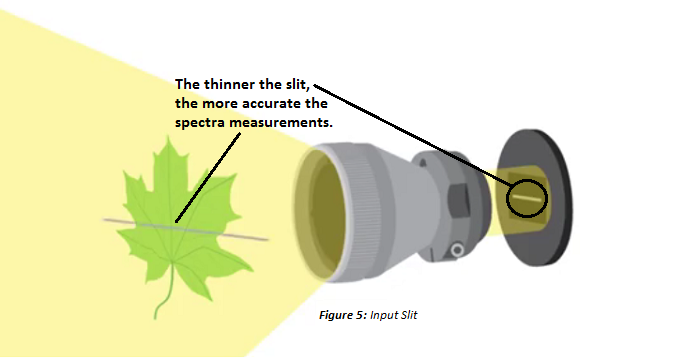

The objective lens forms an image at the input slit. The input slit limits the incoming information to pass through a single very thin line, this is why pushbroom cameras are specifically line scan hyperspectral cameras. The input slit is required for accurate spectral measurements. The thinner the slit, the more accurate the spectral measurements. Slits typically vary from a few microns to several tens of microns wide. A wide slit has less spectral resolution but passes more light and so is more sensitive.

|

||

|

|

|

|

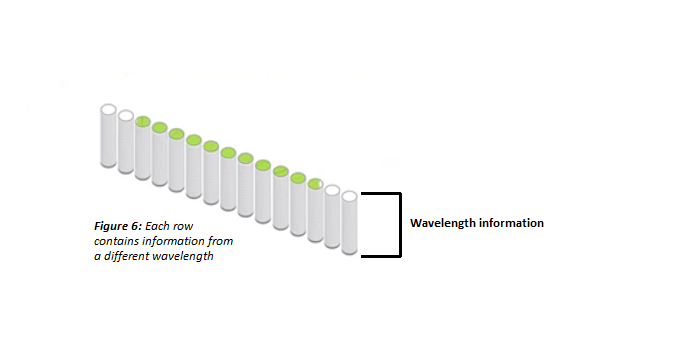

The collimating optics directs the light from the slit to the dispersive unit and passes only parallel light rays aligned to the optical axis. Then the dispersive unit spreads the incoming light into individual spectra onto the camera's sensor vertically. The grayscale camera measures the intensity of the dispersed light at each pixel. Therefore, if we combine the three components of a pushbroom camera, each component plays its role in producing a spectral image. Each row of pixels on the camera sensor contains intensity information at a single wavelength. Every row contains intensity information at a wavelength different from every other row of pixels. Together all rows provide the full spectrum. Another way to describe it is to say that each column of pixels on the sensor contains the spectrum from a single pixel location on the subject being imaged. As the camera (or the subject) moves, full spectral line images are captured repetitively and the full spectra of a 2-dimensional area is captured and stored as a stack of frames. |

||

|

|

|

|

||

|

The cameras are easily integrated and can be installed on new and existing sorting, inspection and production lines. The spectral signature of every pixel can be analysed in real time with Chemical Imaging software also available from Adept Turnkey. The final chemical imaging result can then be used to measure, classify and detect and provide a high level of quality control.

|

||

|

|

|

|

|

If you like this page, please recommend and share it. |

|||

| More | |||