|

||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||

Adept Turnkey appointed Aust/NZ exclusive distributor for LMI Gocator series of 3D smart sensor laser line profilers

Go

to Gocator 2000 series

Go

to 3D Cameras

Go

to LMI Gocator

Offering new-breed, pre-calibrated and affordable 3D sensors to the Australian/New Zealand market

Adept Turnkey Pty Ltd is pleased to have been appointed sole

distributor of the LMI Gocator 2000 series of smart 3D sensors

bringing a range of affordable, industrial 3D measurement devices to the

Australian market. The addition of this new category of 3D smart camera

technologies to Adept Turnkey's portfolio of products provides

all-in-one solutions that are flexible, powerful, easy to use,

competitively priced and applicable to a wider range of industry

situations.

About LMI Technologies

With headquarters in Vancouver, Canada, LMI Technologies is a leading

developer and manufacturer of 3D measurement tools, contributing 30 years

expertise in developments to machine vision technology for factory automation

using 3D technologies. LMI's portfolio of products includes the Gocator

series of flexible 3D sensors - a family of products that provide a variety

of metrology and error-proofing solutions for factory automation. The

powerful and easy-to-use sensors were developed to carry out 3D

inspection and integrate with factory I/O - even without the know-how

of a system integrator or machine vision expert.

About LMI Gocator series

LMI Gocator is a true stand-alone system, with no additional controllers

required.

Data transmission

The sensor can be accessed via industry standard Ethernet and simple cabling

is provided for inputs, outputs, and power. Versatile I/O capabilities

allow the camera trigger to be chosen from time, encoder, external input,

or software, while data and decisions can be transmitted a via RS-485

serial output channel or measurement decisions can be output digitally

to external devices or measurement values and  decisions

can be converted to analogue output signals.

decisions

can be converted to analogue output signals.

Easy to deploy and to use

Built-in web connectivity enables users to access the sensor from any

PC without additional software, drivers, control boxes, amplifiers, or

dependency on a specific operating system. Calibration is extremely straightforward

since the integral laser and camera are precision factory aligned to provide

consistent, reliable measurements in real-world coordinates, even in applications

where temperature variation normally would introduce measurement errors.

The field of view ranges from 14 mm to 1260 mm depending on the Gocator

model selected. Advanced features include dynamic exposure modes to deal

with surfaces with a high variation of surface reflectivity where the

camera combines multiple exposures to deliver an accurate profile every

time.

The LMI Gocator can seamlessly link to a second camera to provide a host

of measurement possibilities. Profile data from both cameras are combined

using a single GUI to measure, make decisions, and show results as if

they came from a single sensor.

| Key features: A family of 3D line profilers designed for part inspection gauging and error-proofing using a series of easy-to-use, built-in tools to measure key parameters |

||

| ** Flexible 3D laser line profilers | ** Standalone smart inspection sensors | ** Provide height and contour data, even on low contrast surfaces |

| ** Web browser setup and control | ** Compact, lightweight and easy to mount | ** Measure key parameters by using a series of easy to use built-in tools ** |

| ** No coding necessary | ** Record and playback sessions to refine tolerances | ** Output data and decisions to a wide variety of external controls |

| ** Export to CSV for later analysis | ** Supports multi-sensor networks with up to 24 sensors of more | ** No external controllers required |

| Quick specs | LMI Gocator

2020 |

LMI Gocator

2030 |

LMI Gocator

2040 |

LMI Gocator

2050 |

LMI Gocator

2070 |

LMI Gocator

2080 |

| Scan rate/speed | 300-5000 Hz dependent

on window size

|

|||||

| Resolution (Z) |

0.003 - 0.011 mm

|

0.008 - 0.018 mm |

0.017 - 0.049 mm |

0.025 - 0.092 mm | 0.07 - 0.023 mm |

0.094 - 0.55 mm |

| Resolution (X) |

0.030 - 0.04 mm

|

0.088 - 0.15 mm |

0.19 - 0.34 mm |

0.30 - 0.60 mm | 0.55 - 1.1 mm |

0.75 - 2.2 mm |

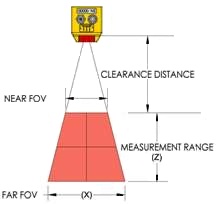

| Clearance Distance (see diagram below) |

40 mm

|

90 mm |

190 mm |

300 mm | 400 mm |

350 mm |

| Measurement Distance (see diagram below) |

20 mm

|

80 mm |

210 mm |

400 mm | 500 mm |

800 mm |

| Field of View (FOV) (see diagram below) |

19 - 26 mm

|

47-85 mm |

96 - 194 mm |

158-365 mm | 308 - 687 mm |

390 - 1260 mm |

| Interface | Ethernet |

Ethernet |

Ethernet |

Ethernet | Ethernet |

Ethernet |

| Size | 65x75x142 mm |

65x75x142 mm |

65x75x194 mm |

65x75x272 mm | 65x75x272 mm |

65x75x272 mm |

| Weight | <1.5 kg |

|||||

| Housing | Gasketed aluminium

enclosure, IP67 |

|||||

|

Diagram showing sensor scan zone |

|||||

Adept Electronic Solutions are "The Machine Vision and Imaging Specialists" and distributor of LMI Technologies in Australia and New Zealand. To find out more about any LMI machine vision product please email us at: adept@adept.net.au or call us at Perth (08) 92425411 / Sydney (02) 99792599 / Melbourne (03) 95555621 or use our online contact us page.

|

If you like this page, please recommend and share it. |

|||

| More | |||