|

||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||

ORE Sizing Success - Achieving peak efficiency

ORE3D Canopy Deployment

Many recipients of our Machine Vision newsletter know Adept as a vision technology supplier but are probably unaware of some of the other work we do. The Ore3D system is one such activity. It is a product Adept has developed over the past 7 years and is used by the mining industry as part of their process control to optimize productivity or to increase quality. The Ore3D system measures and continually outputs a full size distribution of ore on a moving conveyor belt. With the resources sector booming and China's demands continually increasing it has become vital for mines to be optimised for maximum output and quality.

Ore3D is an online instrument designed to fit to conveyor belts. It uses laser stereopsis. It is made up of three main components - low power laser light source, machine vision camera and computer software. A low power laser line is generated and directed at an angle across a moving conveyor belt. A camera located and directed vertically over the laser line on the belt, repetitively captures and processes images at high speed of the line distorted by ore on the belt. The system segments and measures individual fragments and then processes this data via a set of sophisticated algorithms to generate a cumulate % passing curve based on mass.

The technique was originally developed by the Division of Exploration

and Mining at the CSIRO and was licensed to Adept for commercialization

8 years ago. Adept was chosen as the commercialization partner by the

CSIRO because of our depth of knowledge with machine vision and our previous

track record with commercialization. Adept has continued to develop the

system to what is now the leading instrument in the world for this task.

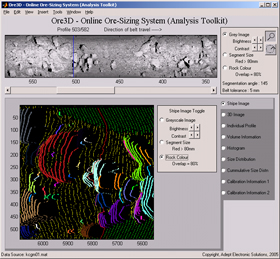

ORE3D System Interface

- SAG mill feed size control

- fragmentation measurement for blasting optimisation

- plant auditing

- oversize detection

- volume flow rate

- bulk density measure

- screen wear monitoring

- optimized conveyor loading

- truck fill volumes

- crusher performance

For more information please contact us.

|

If you like this page, please recommend and share it. |

|||

| More | |||